Are you wondering about the actual potential of your warehouse? Or looking for opportunities to optimize your operations? Do you want to find out "What if..."? Check the return on your investments and harness artificial intelligence to test new solutions.

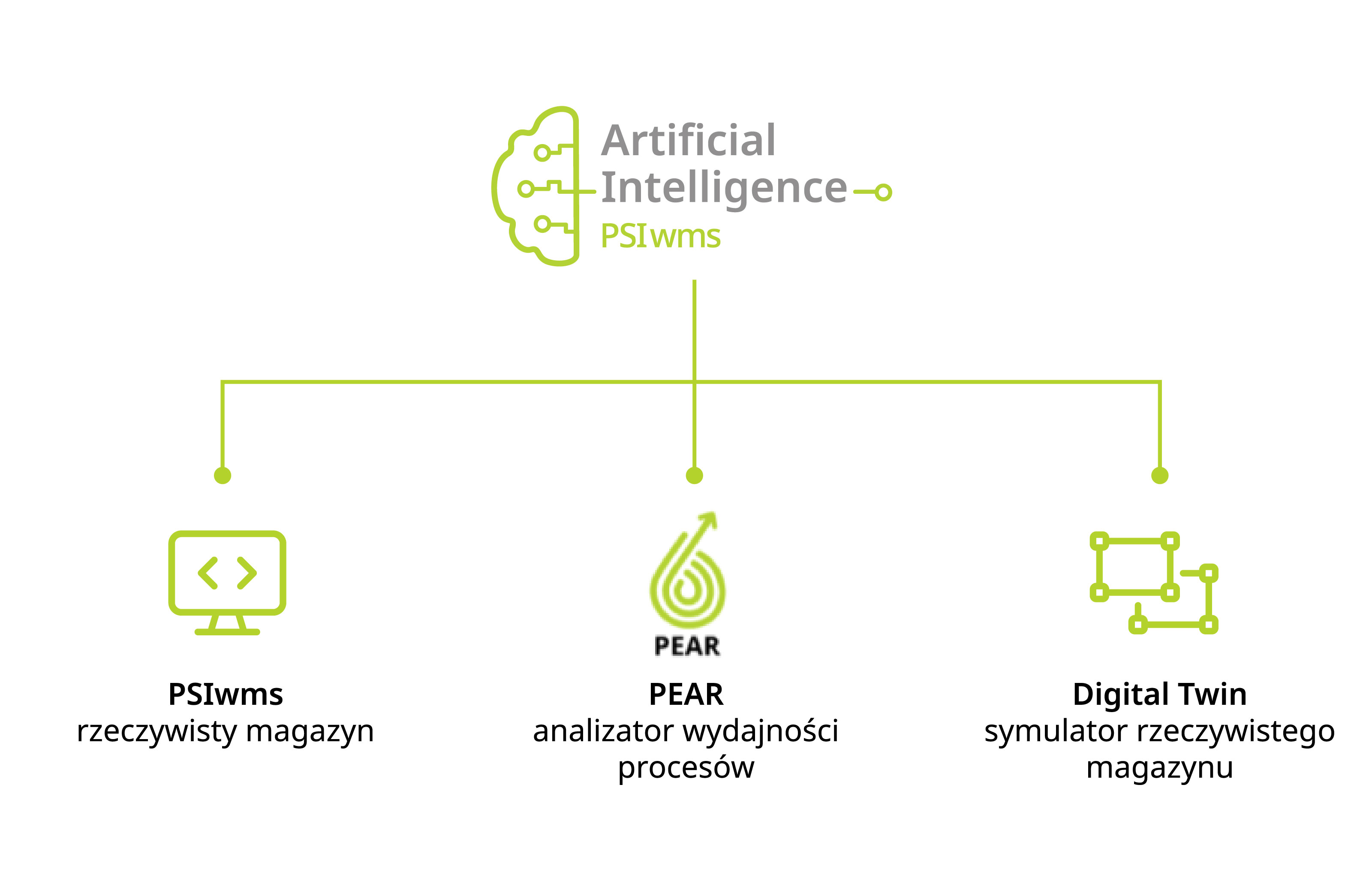

PSIwms AI helps you pick the most optimum logistics strategy and evaluate the impact of potential changes on the efficiency of your processes. Use advanced AI algorithms and mechanisms that will drive the right business decisions.

Using a digital twin, PSIwms AI will analyze various scenarios of warehouse operations and offer improvement recommendations, all based on artificial intelligence and machine learning solutions integrated directly with PSIwms. As a result, any changes in the physical warehouse are automatically fed into the digital twin and incorporated into your analyses in real time.

A Digital Twin reflects all key logistics operations and is linked via a suitable interface to the WMS. Simulations are based on real-life operational data and WMS functionalities.

goods picking paths shorter by approximately

process efficiency higher by more than

an option to analyze process modifications before their implementation

optimal creation of order groups

*data from pilot implementation in LPP’s warehouse

With PSIwms AI, you can perform high-precision simulations (based on real-life data) of any changes in the topology of your warehouse; predict the impact of newly purchased warehouse automation equipment on productivity figures; and verify whether the warehouse staff are able to handle the upcoming sales peak. With PSIwms AI in place, you can:

perform analysis of multiple warehouse operations scenarios in a short period of time

analyze various "what if..." scenarios

identify bottlenecks by visualizing warehouse traffic volumes

model new processes in a digital copy of a real-life warehouse (Digital Twin)

select optimum parameters of logistics processes based on multi-criteria analysis

use data from simulations to train ML algorithms for continuous optimization

Selection of orders for batches

Create and compare best orders strategies for batches.

Make the most of existing logistics resources

Goods reservation

Reserve goods optimally using advanced clustering.

Setting optimum picking paths

Check the best order picking paths.

Coordinate people and resources.

Optimize your picking paths.

Want to optimize your picking paths and arrangement of orders? PSIwms AI will propose most optimum picking paths or arrangement of goods. It will help you predict higher staffing requirements for rising order volumes.

How to determine the impact of a new sorter or rearrangement of warehouse topology on pro-cess efficiency? PSIwms AI allows you to estimate the effects of potential or planned investments and changes. The user is informed whether a particular decision, e.g. pur-chase of a new sorter, will bring actual profits and how it will impact business operations.

Thanks to the solution implemented, the length of picking routes has been reduced by up to 31%, as initial tests show. This also means a significant increase in the efficiency of the picking process itself.

Sebastian Sołtys, CEO of LPP Logistics

Form